Table of Contents >> Show >> Hide

- What an Oscilloscope Really Does (No Mystical Hand-Waving Required)

- Why Put a Scope on Your Wrist?

- The Reality Check: A Wrist Scope Has Limits (Physics Is a No-Fun Bureaucrat)

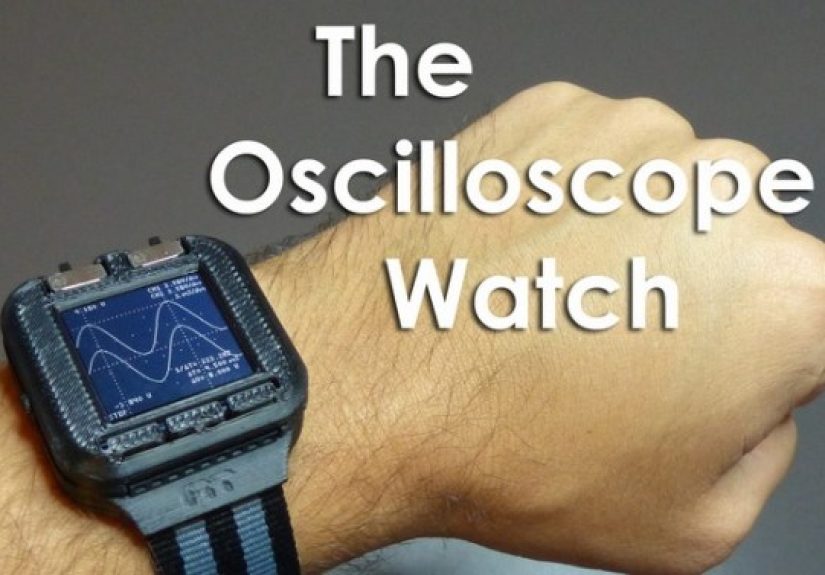

- A Real Example: The Oscilloscope Watch (Yes, It’s a Real Product)

- What You Can Actually Do With a Wrist Oscilloscope

- Wrist Scope vs Pocket Scope vs Bench Scope

- Design Challenges (and Why a Wrist Oscilloscope Is Harder Than It Sounds)

- Safety Notes (Because Electricity Does Not Respect Confidence)

- The Future: Wearable Test Gear That Feels Normal

- Conclusion: A Tiny Scope, A Big Shift in How You Debug

- Field Notes: of Realistic “Wrist Scope” Experiences

There are two kinds of people in this world: people who wear watches to tell time, and people who wear watches to tell

time and interrogate electrical signals like a tiny detective. If you’re reading this, odds are you’re at least

curious about the second group (welcome, we have snacks… and extra jumper wires).

A wrist-worn oscilloscope sounds like a joke someone would make after inhaling too much solder smoke:

“What if my watch could plot waveforms?” And yetthis is not sci-fi. Wearable test gear exists, and it’s part of a bigger

trend: shrinking the electronics bench until it can fit in a pocket, a backpack, or, yes, strapped to your arm like a

particularly nerdy superhero gadget.

This article breaks down what a wrist oscilloscope actually is, what it’s genuinely good for, where it’s absolutely not a

replacement for a bench scope, and why it might be the most oddly practical flex you can bring to a maker meetup.

Along the way, we’ll use a real-world examplethe Oscilloscope Watchto keep the discussion grounded in

reality, not vibes.

What an Oscilloscope Really Does (No Mystical Hand-Waving Required)

At its core, an oscilloscope draws a picture of voltage over time. That’s it. That’s the magic trick. But that “picture”

can reveal a ridiculous amount:

whether a signal is clean or noisy, whether a microcontroller pin is actually toggling, whether a sensor output is drifting,

whether your “square wave” looks suspiciously like a marshmallow.

Modern digital oscilloscopes sample an incoming signal many times per second, store those samples, then display them as a

waveform. The more you sample (sample rate) and the faster your front-end can faithfully respond (bandwidth), the more

truth you can captureespecially for fast edges and higher-frequency content. Triggering is the other secret sauce:

it lets the scope “lock” onto a repeatable moment (like a rising edge) so the waveform stops rolling around like a runaway

shopping cart.

The three specs everyone mentions (and why they matter)

-

Bandwidth: how high in frequency the scope can measure with reasonable accuracy. Think of it like the

“speed limit” of the analog front-end. -

Sample rate: how many measurements per second the scope takes. Higher sample rates capture detail and help

avoid aliasing weirdness. -

Record length (memory depth): how much of the sampled signal you can store at once. More memory means you can

capture longer events without sacrificing time resolution.

A wrist oscilloscope plays in the same sandboxbut with smaller numbers, smaller screen space, and a different mission:

quick insight, not lab-grade deep dives.

Why Put a Scope on Your Wrist?

If you’ve ever tried to debug a circuit away from your bench, you already know the pain. The problem is happening

right now, and your options are:

(1) guess,

(2) “trust the code,” or

(3) go find an instrument and a place to set it down that isn’t a wobbly cardboard box.

A wearable oscilloscope is appealing for the same reason multitools exist. It’s not the best screwdriver you’ll ever use,

but it’s the best screwdriver you’ll have on you when the situation gets weird.

Where wrist instrumentation can shine

- Field troubleshooting: quick checks on PWM, sensor outputs, slow buses, or control signals.

- Education: turning abstract “signals” into something you can literally see anywhere.

- Embedded development: verifying that a pin is doing what your firmware swears it’s doing.

- “Just one measurement” moments: confirming frequency, duty cycle, ripple, or a timing relationship.

The wrist form factor adds something subtle: you’re less likely to skip measurement when measurement is frictionless.

When a tool is always present, “I’ll check it real quick” becomes the default instead of “eh, it’s probably fine.”

(Famous last words in electronics.)

The Reality Check: A Wrist Scope Has Limits (Physics Is a No-Fun Bureaucrat)

A wrist oscilloscope is fundamentally constrained by size, battery, and interface. The smaller the device, the harder it is to

include high-performance analog front-ends, big memory, large displays, and comfortable controls. That doesn’t make it useless

it makes it specialized.

Expect these tradeoffs

- Lower bandwidth: Many wrist/pocket instruments focus on low-to-mid frequency work rather than RF or high-speed serial.

- Shorter captures: Limited record length means you may catch “what’s happening,” but not hours of history.

- Smaller UI: Fewer knobs and less screen real estate mean setup can be slower than a bench scope for complex tasks.

- Probe handling: The best scope in the world can’t help if your connections are unstable or unsafe.

The key mindset shift is this: a wearable scope is not trying to replace your benchtop instrument. It’s trying to help you

avoid debugging blind when you’re away from it.

A Real Example: The Oscilloscope Watch (Yes, It’s a Real Product)

Let’s anchor this in something concrete: the Oscilloscope Watch, a long-running electronics-geek dream that

went from crowdfunding saga to an actual device you can buy. It’s essentially a compact mixed-signal lab strapped to your wrist:

oscilloscope + logic analyzer + waveform generator + protocol sniffing features, plus normal watch functions.

What it packs in (high level)

- 2-channel oscilloscope for analog signals

- Logic analyzer for digital signals

- Arbitrary waveform generator (AWG) to inject test signals

- Protocol sniffing (think common buses like UART/I2C/SPI)

- Watch functions like time, calendar, alarm

Specs that tell you what it’s built for

The published numbers paint a clear picture: this isn’t a high-speed lab monster. It’s a wearable “get answers fast” tool.

The oscilloscope section is rated for up to 4 MSPS sampling with 200 kHz analog bandwidth,

8-bit resolution, 1 MΩ input impedance, and an input voltage range listed as

-14 V to +20 V. The buffer per channel is listed as 1k samples, which favors quick snapshots over

long recordings.

On the digital side, it lists 8 digital inputs with up to 16 MSPS, plus protocol sniffing and a

frequency counter (handy when you care more about “how fast is it?” than “what’s the exact shape?”).

The built-in waveform generator is rated up to 1 MSPS with about 50 kHz bandwidth and around

±4 V output.

Ergonomics matter too. The watch uses a compact 1.28-inch 128×128 display, a small battery (listed as

400 mAh), and multiple buttons for navigation. It’s also refreshingly honest about one very “real world” detail:

the enclosure is not waterproof. Translation: it’s a scope watch, not a scuba watch.

A wrist oscilloscope is the ultimate “I don’t need it… until I absolutely need it” device.

What You Can Actually Do With a Wrist Oscilloscope

The best way to understand a wearable scope is through situations where it saves time (and sanity). Here are realistic,

low-to-mid frequency tasks where a wrist oscilloscope can earn its keep.

1) Confirm your PWM isn’t lying to you

Say you’re driving an LED strip, a fan controller, or a motor driver with PWM. Your code says 25% duty cycle, but the motor

sounds like it’s auditioning for a horror movie soundtrack. A quick look at the waveform tells you whether you’re getting:

clean edges, a stable period, and the duty cycle you intendedor a noisy, jittery mess caused by timer misconfiguration or load issues.

2) Spot sensor ripple, noise, and “mystery wobble”

Many sensors output slow analog voltages. That’s great news for a wrist scope. You can check whether your “steady” signal has

ripple from a switching regulator, random spikes from a motor, or a slow drift that explains why your readings look different

every time you blink.

3) Check common digital buses at human-scale speeds

Not every digital signal is a GHz rocket ship. Plenty of real devices run I2C at 100 kHz or 400 kHz, SPI at modest speeds,

UART lines for modules, GPS units, and debug outputs. A logic analyzer view (especially with protocol decoding) can quickly tell

you whether traffic exists, whether the line is stuck, or whether your pull-ups are doing their job.

4) Use the built-in waveform generator like a tiny signal whistle

A waveform generator on your wrist sounds silly until you’re testing a filter, amplifier, or RC circuit. Inject a sine wave,

square wave, or sweep, then observe the output. Even with modest bandwidth, this is enough to validate “does this stage behave

like the schematic promised?” without hauling out a bench generator.

5) Quick education demos anywhere

One of the most underrated uses: teaching. If you’re mentoring a beginner, showing an RC charge curve, a rectifier ripple,

or the phase difference between two signals makes concepts stick immediately. A wearable tool lowers the barrier to those

“show me” momentsno lab required.

Wrist Scope vs Pocket Scope vs Bench Scope

Think of test equipment like transportation:

a bench oscilloscope is a cargo truck (powerful, stable, built for heavy lifting),

a portable ScopeMeter-style tool is an SUV (rugged and field-ready),

a USB instrument is a scooter (small, flexible, relies on something else for display),

and a wrist oscilloscope is… roller skates (surprisingly useful, but you should know what you’re doing).

When the bench scope still wins (by a mile)

- High bandwidth needs (fast digital edges, RF work, modern high-speed serial)

- Deep memory captures and long sessions

- Advanced triggering and analysis workflows

- Comfort and speed of knobs + big screen

When portable tools (including wrist gear) win

- On-site diagnostics where carrying a bench scope is unrealistic

- Industrial environments where rugged design and safety ratings matter

- Quick verification: “Is the signal present and roughly correct?”

- Teaching, demos, and tinkering where convenience beats perfection

A smart workflow is often hybrid: use the wrist tool to find the problem quickly, then bring the circuit back to the bench

when you need deeper analysis.

Design Challenges (and Why a Wrist Oscilloscope Is Harder Than It Sounds)

Strapping an oscilloscope to your wrist isn’t just “make it smaller.” The hard parts are the analog front-end, protection,

grounding, power, and user experience.

Power and display: always-on, but not always-draining

Wearables need to sip power, especially in “watch mode.” A clever display choice and aggressive low-power behavior can give

you months of standby while still enabling hours of active measurement. That split personalityultra-low-power timekeeping

plus bursty measurement workloadsis central to wearable instrumentation.

Input protection: your wrist doesn’t need fireworks

Even modest scopes need protection against accidental overvoltage, static discharge, and user error. A wearable device is even

more likely to be used in unpredictable situations, so the design has to assume “someone will eventually do something spicy.”

Spicy is fun in food. Spicy is expensive in electronics.

Controls: fewer knobs, more thinking

Traditional scopes have dedicated knobs for volts/div and time/div because fast iteration is the whole point. On a wrist device,

you trade that for buttons and menus. The better the firmware and interface design, the more “instant” it feels.

A wrist scope lives or dies by its usability.

Safety Notes (Because Electricity Does Not Respect Confidence)

A wrist oscilloscope can be a wonderful toolif you use it responsibly. Here are non-negotiable safety habits:

- Don’t treat it like a mains-rated instrument unless it explicitly is. Many compact tools are for low-voltage electronics.

- Be careful with grounding. Incorrect ground connections can short parts of a circuit or create hazards.

- When in doubt, step back. If you’re dealing with high energy systems, use properly rated test equipment and procedures.

- Remember the “not waterproof” reality. Water and electronics are a famously dramatic couple.

The goal of wearable instrumentation is conveniencenot gambling.

The Future: Wearable Test Gear That Feels Normal

Today, a wrist oscilloscope is still a niche gadgetbeloved by makers, fascinating to engineers, confusing to normal humans.

But the direction is clear: test gear keeps getting smaller, more integrated, and more software-driven.

What “better” could look like next

- Wireless probes: keeping the measurement front-end near the circuit while the display stays on your wrist

- Deeper memory with smart capture modes: record only when anomalies occur

- Better decoding and analysis: more protocols, better visualization on tiny screens

- Companion apps: wrist for quick look, phone/laptop for serious analysis

The most interesting path might be this: your wrist device becomes the always-available “trigger finger,” and heavier analysis

happens elsewhere. The wrist is the cockpit; the phone or computer is mission control.

Conclusion: A Tiny Scope, A Big Shift in How You Debug

“An oscilloscope on your wrist” is funny because it sounds unnecessaryuntil you’ve been stuck troubleshooting without one.

Wearable measurement tools aren’t here to dethrone your bench scope. They’re here to remove friction, to make verification

habitual, and to give you quick truth when the alternative is guessing.

If your work lives in low-to-mid frequency electronicsembedded signals, sensors, PWM, hobby buses, quick sanity checksa wrist

oscilloscope can be genuinely useful. If your world is high-speed serial, RF, or deep signal integrity, you’ll still want

the big iron. But even then, a wearable tool can be a fast triage device: catch the obvious issues first, then go deeper

when needed.

And yes, it also looks cool. Not “sports car” cool. More like “I can explain why your dimmer flickers” cool. Which, frankly,

is the best kind.

Field Notes: of Realistic “Wrist Scope” Experiences

Imagine a typical maker day: you’re bouncing between a breadboard prototype, a half-assembled enclosure, and a laptop covered

in stickers that scream “I solve problems, but only after coffee.” The project is simple on paperread a sensor, drive a fan,

log databut reality has opinions.

The first weird symptom: the fan audibly surges every few seconds. Your code looks fine, your power supply looks fine, and your

confidence is… aggressively fine. Instead of tearing everything apart, you clip onto the PWM line and take a look. The duty cycle

is drifting, not smoothly, but in little jumps. That’s not a “bad fan.” That’s a timer configuration issue or an interrupt routine

stepping on your timing. You fix one line of code, re-check, and the waveform settles down. You didn’t “feel” the bug. You saw it.

Later, you’re helping a friend with a sensor module that “works sometimes.” Classic. The output voltage should be steady, but the

readings wander. A quick look at the analog line shows a faint ripple riding on the signallike a tiny wave at the beach, except

the beach is your PCB and the tide is your switching regulator. You move a ground connection, add a little decoupling, and the ripple

shrinks. Suddenly the sensor stops acting haunted.

The real joy is the “micro-mystery” moments. Like when an I2C device won’t acknowledge. You don’t need a full laboratory to learn that

the clock line is stuck low. You just need proof. You grab a logic view, see the line pinned, and now you’re debugging pull-ups,

solder bridges, or a miswired connectorspecific suspects, not vague despair.

Then there’s the educational side. Someone asks, “What does an RC time constant actually look like?” You show them. Not in a slide deck.

Not in a textbook. On a waveform. You feed a step-like signal in, watch the curve rise, and suddenly the math has a face. People remember

pictures. Waveforms are pictures that happen to be true.

Of course, it’s not all victory laps. A small screen means you sometimes squint. Buttons mean you occasionally press the wrong thing and

feel personally attacked by menu navigation. And you learn quickly that wearable instruments aren’t “set and forget”they’re “set and verify.”

Stable probe contact matters. Clean grounding matters. And you absolutely do not want to treat a small wearable tool like it’s automatically

safe for every environment.

But when it works, it’s addictive. You stop guessing. You stop narrating your problems like a mystery novel. You measure.

And once measurement becomes easy, your whole debugging style changes: less superstition, more certainty. That’s the real upgradenot the wrist

strap, not the novelty. It’s the habit of checking reality before reality checks you.