Table of Contents >> Show >> Hide

- What a Capacitor Actually Does (In Plain English)

- Safety First: Before You Touch Any Capacitor

- Matching the Right Replacement Capacitor

- Step-by-Step: Replacing a Motor or AC Run Capacitor

- Start vs. Run Capacitors: What’s the Difference?

- How to Wire a Capacitor in a Car Audio System

- Installing Capacitors on a Circuit Board: Polarity Matters

- Common Mistakes to Avoid When Installing a Capacitor

- Real-World Experiences: Lessons From Installing Capacitors

- Wrapping Up

Capacitors are the quiet heroes of the electrical world. They help AC motors start, keep your air conditioner running,

smooth out power for car audio amps, and stabilize voltage in electronic circuits. But if you’ve ever opened a panel

and stared at a shiny metal cylinder or a little barrel-shaped component on a circuit board, you might have wondered:

“How on earth do I install that without frying myself or my equipment?”

The good news: installing or wiring a capacitor is absolutely doable for a careful DIYer. The not-so-good news:

you must respect electricity, follow safety rules, and pay close attention to wiring diagrams and polarity.

In this guide, we’ll walk through easy, step-by-step instructions on how to install a capacitor, whether you’re

replacing a run capacitor on an AC unit, hooking up a motor start capacitor, or wiring a capacitor into a car audio system.

We’ll keep the language simple, the instructions detailed, and sprinkle in a little humor along the way so you don’t fall

asleep on your toolbox. By the end, you’ll know how to choose, wire, and hook up a capacitor safely and confidently.

What a Capacitor Actually Does (In Plain English)

A capacitor is basically an electrical “storage tank” that can charge up and release energy quickly.

Unlike a battery, it charges and discharges rapidly and doesn’t store energy for long periods.

In everyday systems, you most commonly meet capacitors in three situations:

-

HVAC and appliance motors: Start and run capacitors give single-phase motors an extra push to start

and help them run more efficiently. -

Car audio systems: Big “cap” cans help smooth power delivery to the amplifier so your headlights don’t

dim every time the bass drops. -

Electronics and circuit boards: Capacitors filter noise, stabilize voltage, and help timing circuits

work properly.

The key things to remember are:

- Capacitance (measured in microfarads, µF) tells you how much charge it can store.

- Voltage rating tells you the maximum voltage it can safely handle.

- Polarity matters on many capacitors (especially electrolytic ones) and must be respected.

Safety First: Before You Touch Any Capacitor

Capacitors can hold a dangerous charge even after the power is turned off. That’s why safety is not optional.

Always follow these rules:

- Turn off power at the source: For HVAC or appliances, shut off the breaker. For car audio, disconnect the battery’s negative terminal.

- Verify power is off: Use a non-contact voltage tester or a multimeter before you touch anything.

- Discharge the capacitor: Use a resistor or a dedicated discharge tool across the terminals. Don’t just short it with a screwdriver unless a professional guide specifically recommends that method for your application.

- Wear safety gear: Insulated gloves and safety glasses are strongly recommended.

- Work in a dry area: Electricity plus moisture is not the kind of “spark” you want in your life.

If you ever feel unsure, it’s safer (and often cheaper in the long run) to call a licensed technician or electrician.

Matching the Right Replacement Capacitor

Before you start wiring anything, you need the correct part. Using the wrong capacitor can cause poor performance,

repeated failures, or permanent damage to your equipment.

1. Match the Microfarad (µF) Rating

The microfarad (µF) value is not a suggestion; it’s a requirement. If your original run capacitor is rated 35 µF,

your replacement must also be 35 µF (or as close as the manufacturer’s tolerance allows). Changing this value can alter

motor performance and shorten its life.

2. Check the Voltage Rating

The voltage rating on the capacitor is a maximum limit. You must never go below the original voltage rating.

Using a slightly higher voltage rating (for example, replacing a 370V cap with a 440V cap) is generally acceptable,

but going from 440V to 370V is not.

3. Confirm Type and Use

Make sure you’re buying the right kind of capacitor:

- Run capacitor vs start capacitor for motors.

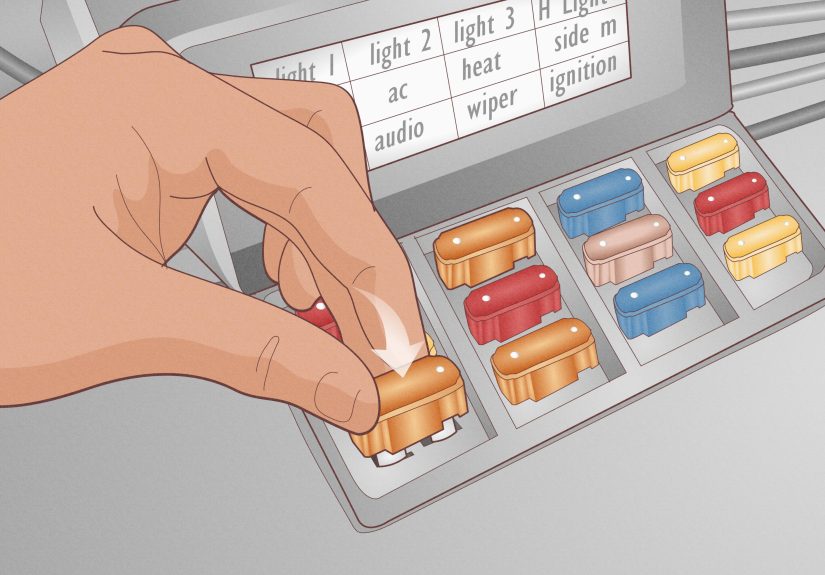

- Dual run capacitor (often labeled C, FAN, HERM) for many air conditioners.

- Electrolytic capacitor vs film capacitor in electronics.

- Specialized car audio capacitor (measured in farads) for amps.

When in doubt, check the wiring diagram on the motor, equipment label, or owner’s manual. Don’t guess.

Step-by-Step: Replacing a Motor or AC Run Capacitor

This is the classic scenario: your AC fan isn’t starting, or a motor just hums instead of spinning. One of the most

common culprits is a bad run capacitor. Here’s a general process many HVAC guides follow, adapted into clear DIY steps.

Always respect the specific wiring diagram for your unit.

Step 1: Shut Off Power and Open the Panel

- Turn off the breaker that feeds the unit or appliance.

- Verify with a voltage tester that no power is present.

- Remove the service panel or access cover to locate the capacitor.

On an outdoor AC unit, the capacitor is usually a metal cylinder or oval can mounted inside the electrical compartment.

It may be a dual run capacitor with three labeled terminals.

Step 2: Inspect and Identify the Terminals

Take a careful look at the old capacitor:

- Check for bulging, leaking oil, rust, or burn marks.

- Note the labels on top: commonly C (Common), FAN, and HERM (for compressor).

- Before removing any wires, take a clear photo with your phone so you can reconnect them exactly as they were.

Step 3: Discharge the Old Capacitor

Even with the power off, the capacitor may still be charged. To discharge:

- Use a resistor (for example, a 2K–20K ohm, 5–10W resistor) with insulated leads.

- Connect it across the capacitor terminals for several seconds to safely bleed off the charge.

- Double-check with a multimeter if you have one and know how to use it.

Avoid random metal-on-metal shorting unless a specific professional procedure calls for itarcing isn’t just loud,

it can damage the terminals.

Step 4: Remove and Label the Wires

- Gently pull the wire terminals off the capacitor using insulated pliers.

- If you didn’t take a photo earlier, label each wire with tape: C, FAN, HERM, or as indicated.

- Unscrew or unclip the capacitor from its mounting bracket.

Step 5: Mount and Wire the New Capacitor

- Place the new capacitor in the bracket and secure it firmly so it doesn’t vibrate loose.

- Reconnect each wire to the correct terminal:

- All wires that were on C go to C on the new capacitor.

- All wires that were on FAN go to FAN.

- All wires that were on HERM go to HERM.

- Double-check each connection against your photo and the wiring diagram.

Step 6: Close Up and Test

- Reinstall the access panel.

- Turn the breaker back on.

- Call for cooling or start the equipment and watch it run.

The fan or compressor should start smoothly without humming or stalling. If it still won’t start, turn the power back

off and consider calling a prothere may be a deeper issue.

Start vs. Run Capacitors: What’s the Difference?

You’ll often see two types of motor capacitors:

- Start capacitors: High-capacitance units that give the motor a big kick when it starts. They’re in the circuit only briefly.

- Run capacitors: Lower-capacitance units designed to stay in the circuit and optimize efficiency and torque while the motor runs.

Some motors have both, and some AC units use a dual run capacitor that serves both the fan and compressor in a single can.

Always replace like with like: a start cap with a start cap, a run cap with a run cap, and a dual run cap with the same

ratings and terminal configuration.

How to Wire a Capacitor in a Car Audio System

If you’re into car audio, you may add a large capacitor (often 1–5 farads) to stabilize voltage when the amp demands

big bursts of current. The basic wiring steps look like this:

- Size the capacitor: A common rule of thumb is about 1 farad per 1,000 watts of amplifier power.

- Disconnect the battery: Remove the negative terminal before doing any wiring.

- Mount the capacitor: Secure it close to the amplifier to minimize power loss and wiring length.

- Pre-charge the capacitor: Many car audio capacitors must be charged slowly using a resistor or charging bulb before full connection. This prevents a dangerous surge.

- Wire in parallel:

- Connect the capacitor’s positive terminal to the amp’s positive power input.

- Connect the capacitor’s negative terminal solidly to chassis ground.

- Reconnect the battery and test: Check that the system powers up normally and that lights dim less on bass hits.

As always, follow the capacitor manufacturer’s wiring diagram and instructions. Car wiring mistakes can lead to blown

fuses, melted wires, or worse.

Installing Capacitors on a Circuit Board: Polarity Matters

On a printed circuit board (PCB), installing a capacitor is more delicate, but the principle is the same: the right part,

the right orientation, and secure connections. The trickiest part is polarity.

How to Recognize Polarized Capacitors

Most electrolytic capacitors are polarized. Here’s how manufacturers usually mark them:

- The negative side often has a stripe or “−” symbols printed on the body.

- The positive lead is sometimes longer on through-hole components.

- On tantalum capacitors, the positive terminal is usually marked with a “+”.

The circuit board itself often has markings too: a “+” sign, a clear “–” indicator, or a shaded half-moon showing which

pad is negative.

Basic PCB Capacitor Installation Steps

- Identify the correct part: Match capacitance (µF) and voltage rating with the original component.

- Check polarity: Align the capacitor’s positive lead with the board’s positive pad and the negative lead with the negative pad.

- Insert the leads: Gently bend if needed so the capacitor sits flat without stress on the leads.

- Solder: Heat the pad and lead, then apply solder to form a clean, shiny joint. Avoid overheating the capacitor.

- Trim excess leads: Clip off extra lead length on the underside of the board.

Reversing polarity on an electrolytic capacitor isn’t just “not ideal.” It can cause leakage, overheating, or in worst

cases, an explosive failure. Double-check your orientation before powering up.

Common Mistakes to Avoid When Installing a Capacitor

- Guessing the wiring: Never “wing it.” Use the wiring diagram, labels, or a photo of the original setup.

- Ignoring microfarad ratings: Using the wrong µF value can make motors run hot, noisy, or weak.

- Underrating voltage: A lower voltage rating than the original is a fast way to destroy a new capacitor.

- Skipping discharge: Forgetting to discharge a capacitor can result in painful or dangerous shocks.

- Mixing up start and run capacitors: They aren’t interchangeable; they’re built for different duties.

- Leaving components loose: A loosely mounted capacitor can vibrate, break connections, and fail early.

Real-World Experiences: Lessons From Installing Capacitors

Installing a capacitor looks simple on paper: disconnect, swap, reconnect. In reality, the details matter.

Here are some real-world style lessons and “experience tips” that make the job smoother and safer.

Label Everything Like Future-You Has Amnesia

One of the most common DIY mistakes is trusting your memory. You remove three or four wires, get distracted,

come back five minutes later, and suddenly every spade connector looks identical. Take a photo before touching anything.

If the wiring is complex, use masking tape and a marker to label each wire. Future-you will be grateful.

A lot of technicians do this automatically because they’ve learned the hard way: the extra 30 seconds of labeling is

much cheaper than miswiring a compressor or motor and having to replace more than a capacitor.

Don’t Cheap Out on the Part

It’s tempting to grab the cheapest replacement capacitor you can find online. But bargain-basement parts often have

poor tolerances and low-quality internal construction. In high-stress environments like AC units or heavy-duty motors,

that can mean another failure in a few months.

When possible, choose reputable brands, and stick with the µF value and equal-or-higher voltage rating recommended by

the equipment manufacturer. A few extra dollars now can prevent repeat troubleshooting later.

Mounting Matters More Than You Think

Vibrations and heat are the natural enemies of capacitors. In outdoor AC units, for example, the capacitor sits in a

place that can get hot and shaky. If it’s loosely strapped in or dangling by its wires, those forces will work on the

terminals and internal connections until something gives.

Always mount the capacitor securely in its bracket or clamp. Avoid placing it right next to resistors, coils, or other

parts that run very hot. Good mechanical support can extend its life significantly.

Understand the Symptoms of a Bad Capacitor

Installing a new capacitor is satisfying, but it’s even better when you really understand what problem you just fixed.

Common signs of a failing capacitor include:

- A motor that hums but doesn’t start.

- An AC fan that randomly stalls or takes a long time to spin up.

- Repeated breaker trips when equipment tries to start.

- Car audio lights dimming dramatically with bass hits.

- Bulging, leaking, or rusted capacitor cans.

Knowing these signs helps you diagnose faster in the futureand helps you appreciate just how much work that little

component does behind the scenes.

Respect Polarity Like a Hard Rule, Not a Suggestion

Many first-time electronics hobbyists learn about capacitor polarity the hard way. Hooking an electrolytic capacitor

in backwards might not do anything dramatic at low voltages, but at higher voltages or over time, the capacitor can heat

up, vent, or even pop.

Get into the habit of:

- Finding the “+” or “−” markings before you even pick up the soldering iron.

- Double-checking the board’s silk-screen markings.

- Taking a clear photo of the original component’s orientation if you’re replacing it.

Over time, this becomes second nature and saves you a lot of rework (and jump scares from “surprise” capacitor failures).

Know When to Call a Professional

While many capacitor installations are beginner-friendly, there are situations where experience truly matters.

Complicated multi-capacitor banks, industrial power-factor correction, and high-voltage systems are not ideal first DIY

projects. If you’re dealing with high voltages, unusual wiring diagrams, or equipment under warranty, hiring a pro can

protect both your gear and your safety.

A good rule of thumb: if you don’t fully understand what each wire does or can’t confidently identify the capacitor

ratings and terminals, it’s time to get expert help.

Wrapping Up

Installing a capacitor isn’t magic, and you don’t need a degree in electrical engineering to do it safely.

With the right part, a careful eye on ratings and polarity, and a methodical step-by-step approach, you can replace

a bad run capacitor in your AC, wire a car audio capacitor, or swap a PCB capacitor without drama.

Treat electricity with respect, take more photos and labels than you think you need, and never guess on wiring.

Do that, and your newly installed capacitor will quietly get to workhelping motors start, systems run smoothly,

and music hit just that little bit harder.