Table of Contents >> Show >> Hide

- Before You Build: Rules, Reality, and Roadside Survival

- Design Choices That Make Your Brick Mailbox Look Expensive (Without Actually Being Expensive)

- Tools and Materials Checklist

- Step-by-Step: How to Make a Brick Mailbox

- Step 1: Lay out the position and confirm delivery alignment

- Step 2: Excavate and prepare the base

- Step 3: Build the reinforced concrete footing/pad

- Step 4: Build the CMU block core (the backbone)

- Step 5: Set the mailbox insert correctly

- Step 6: Core-fill and reinforce for long-term stability

- Step 7: Lay the brick veneer (the “wow” layer)

- Step 8: Tool the joints and clean as you go

- Step 9: Install the cap (and make water roll away)

- Step 10: Add finishing touches

- Common Mistakes (So You Can Skip the “Character Building” Part)

- Maintenance Tips to Keep It Looking Sharp

- of Real-World Brick Mailbox Experience (The Part You’ll Thank Later)

- Conclusion

A brick mailbox is the tuxedo of curb appeal. It says, “Yes, I receive coupons and jury duty notices,

but I do it with dignity.” It’s also sturdier than the leaning wooden post you’ve been side-eyeing

since 2017. If you’re ready to build a brick mailbox that looks legit, stays plumb, and doesn’t annoy

your mail carrier, you’re in the right place.

This guide walks you through planning, permits, foundation work, a reinforced block core, bricklaying,

and finishing detailsplus the little real-world “oops” moments that DIYers only learn the fun way.

Let’s build something you’ll be proud to point at when guests pull up… and something your delivery

driver won’t accidentally take out with a side mirror.

Before You Build: Rules, Reality, and Roadside Survival

Check mailbox placement (yes, it matters)

Mailboxes aren’t freestyle art installationsplacement is typically expected to follow USPS guidance.

As a general rule, the point of mail entry should land about 41–45 inches above the road surface,

and the face of the mailbox should sit about 6–8 inches back from the curb or road edge.

If you don’t have a curb, your local post office can tell you what they want for your street. Do this

step early; it’s a lot easier to move a string line than a half-ton of masonry.

Call 811 before you dig

A brick mailbox needs a real foundation, and foundations involve digging. In the U.S., call 811

to locate underground utilities. Striking a line turns your “weekend project” into a “news story,” and

not the heartwarming kind.

Permits, HOA rules, and local codes

Some cities and HOAs have rules about mailbox styles, height, materials, and setbacks from the road.

Many also care about visibility at intersections and driveway clearance. A quick check can save you

from rebuilding (or receiving a letter that feels suspiciously like a breakup).

Frost heave is realplan your foundation accordingly

In freeze-thaw climates, shallow foundations can shift and tilt. Local codes vary, but the safest approach

is to build a foundation system that resists movement: a well-compacted base, a reinforced concrete pad,

andwhen neededan extended pier or footing depth that addresses your area’s frost line. If you’re unsure,

ask your local building department or a mason. “I eyeballed it” is not a structural strategy.

Design Choices That Make Your Brick Mailbox Look Expensive (Without Actually Being Expensive)

Pick a mailbox insert first

Don’t build the brick column and then discover your mailbox insert is too tall, too deep, or opens into

your brickwork like a tiny guillotine. Choose a USPS-approved mailbox or a masonry mailbox insert

designed for brick columns. Decide whether you want:

- Front access (carrier delivers and you retrieve from the front) simplest, but you stand by the road.

- Rear access (carrier front, you rear) more convenient, often more “premium,” slightly more planning.

- Locking mailbox better security, but confirm carrier access is still practical.

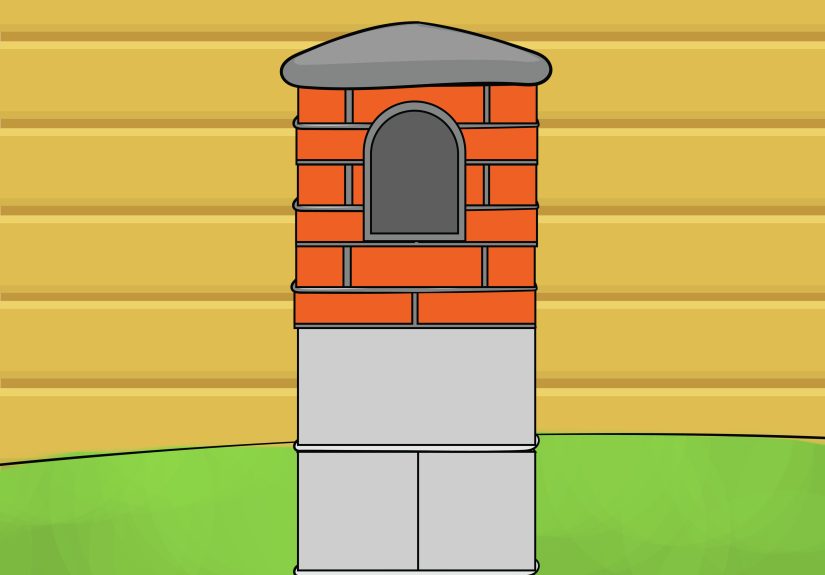

Choose your look: full brick vs. brick veneer

Most durable DIY builds use a reinforced concrete block (CMU) core with a brick veneer.

That gives you strength inside and curb-appeal outsidelike wearing boots under dress pants.

Don’t forget the cap and water management

Water is the silent villain of masonry. A sloped, overhanging cap (stone, precast concrete, or brick cap)

helps shed water and reduces freeze damage, staining, and mortar deterioration. If you want your mailbox

to age gracefully, give rain somewhere else to hang out.

Tools and Materials Checklist

Materials

- Mailbox insert (and hardware)

- Concrete mix (for footing/pad and for core fill)

- Gravel (base layer for drainage and leveling)

- Rebar (typically vertical bars; size depends on design/local requirements)

- CMU blocks (commonly 8x8x16) for the core

- Brick (plus a few extra for cuts and “learning opportunities”)

- Mortar mix (Type N is common for above-grade veneer work; follow local recommendations)

- Brick ties/anchors (if your design calls for them)

- Mailbox cap (stone, precast, or brick cap materials)

- Address numbers/plate

- Optional: conduit or sleeve (if you want lighting later)

Tools

- Shovel, digging bar, wheelbarrow (your new gym membership)

- Level (2-foot and/or 4-foot), framing square, tape measure

- Mason’s string line and line blocks

- Trowels (brick trowel + pointing trowel), jointer/tool for finishing mortar joints

- Rubber mallet, brick hammer, and/or masonry saw with diamond blade

- Rebar cutter/bender (or a plan for cutting rebar safely)

- Mixing tub or mixer, hoe or paddle mixer

- Safety gear: gloves, eye protection, dust mask, hearing protection

Step-by-Step: How to Make a Brick Mailbox

Step 1: Lay out the position and confirm delivery alignment

- Mark the mailbox centerline where the carrier can reach safely from the vehicle.

- Confirm height and setback targets (and check with your local post office if your road is unusual).

- Use stakes and string to outline the footprint of the mailbox column and any decorative base.

- Double-check driveway clearance and visibility (especially near corners).

Step 2: Excavate and prepare the base

Dig a square or rectangle large enough for your foundation pad. Size depends on your design and soil,

but a common DIY pattern is a pad wider than the column footprint to spread load and resist leaning.

In cold regions, consider a deeper center pier or deeper footing strategy to reduce frost movement.

- Excavate to your planned depth (and to stable, undisturbed soil where possible).

- Add a compacted gravel layer (often a few inches) for drainage and leveling.

- Compact wellpoor compaction is a top cause of settling and tilt.

Step 3: Build the reinforced concrete footing/pad

Your brick mailbox is only as straight as the concrete beneath it. Take your time here.

A reinforced pad helps distribute weight, resist cracking, and keep the column from slowly

auditioning for the Leaning Tower of Mail.

- Set simple forms if needed (wood boards work fine).

- Place rebar in the pad area (grid or perimeter reinforcement depending on design).

- Include vertical rebar dowels that will extend into the CMU core (so the mailbox becomes one reinforced system).

- Pour concrete, level it, and finish the top reasonably smooth (it doesn’t need to be countertop perfect).

- Cure properly: keep it damp or covered as recommended for your concrete product, and give it time to gain strength.

Step 4: Build the CMU block core (the backbone)

The core is where strength comes from. Think of the brick veneer as the nice jacket; the CMU core is the

shoulders doing the work.

- Dry-fit the first course of CMU to confirm layout and mailbox insert positioning.

- Lay the first course in mortar, checking level in both directions.

- Stack additional courses, keeping the core plumb and square.

- Thread your vertical rebar through the block cells as you go (aligned with your footing dowels).

- Leave openings and supports ready for the mailbox insert based on the insert’s dimensions and install method.

Step 5: Set the mailbox insert correctly

The insert should be level, aligned to the street, and secured per the manufacturer’s instructions.

Confirm that the door opens cleanly and doesn’t crash into brick. If you’re doing rear access, confirm the

rear door swing and clearance too.

- Use shims or temporary bracing to keep the insert square while surrounding masonry cures.

- Protect the insert from mortar smears (blue tape is your friend).

- Confirm the final mail-entry height before you lock it in forever.

Step 6: Core-fill and reinforce for long-term stability

For a durable masonry column, it’s common to fill reinforced cells with concrete or grout-like mix.

This ties the rebar and block together into a solid unit. Follow best practices and don’t try to fill

everything in one messy, air-pocket-filled blast.

- Mix fill material to the right consistency (flowable enough to settle, not soupy).

- Fill reinforced cells in lifts (stages), rodding or tapping to remove air voids.

- Keep everything plumb while it curesmovement now becomes permanent later.

Step 7: Lay the brick veneer (the “wow” layer)

Now the fun part: the brick. This is where patience pays rent.

- Plan your brick pattern and bond (running bond is common and beginner-friendly).

- Snap or mark guide lines and use a mason’s line to keep courses straight.

- Spread mortar, set bricks, and keep joints consistent.

- Check level and plumb frequently. Tiny errors become big personality traits.

- Cut bricks cleanly where needed (corners, around the insert, decorative banding).

Step 8: Tool the joints and clean as you go

Tooling mortar joints isn’t just aestheticsit compacts mortar, improves water resistance, and makes

the whole thing look professionally finished. Also, cleaning mortar off brick after it hardens is a

hobby for nobody.

- Tool joints when mortar is “thumbprint” firm (not wet, not rock-hard).

- Brush lightly to remove crumbs and smooth the look.

- Use a damp sponge carefully for smears; avoid washing mortar out of joints.

Step 9: Install the cap (and make water roll away)

A proper cap should overhang slightly and shed water away from the brick faces. Use mortar or adhesive

recommended for your cap material, and keep it level with a slight slope where appropriate.

Step 10: Add finishing touches

- Install address numbers large enough to read from the street.

- Seal gaps around the insert if the manufacturer recommends it.

- Optional: add a small solar light or low-voltage lighting (plan wiring early if you go this route).

- Stand back and admire. Take a photo. Your old mailbox post would never.

Common Mistakes (So You Can Skip the “Character Building” Part)

1) Underbuilding the foundation

Most leaning brick mailboxes are not “bad brick jobs.” They’re foundation problems. Compaction, drainage,

and reinforcement matter more than the fanciest brick pattern.

2) Forgetting door swing clearance

If the mailbox door swings down and smacks the brick, you’ll hate using it. Mock it up and test it

before the mortar sets.

3) Rushing mortar work

Mortar that’s too wet slumps; mortar that’s too dry won’t bond well. Mix in small batches until you

learn the feel. And keep your tools cleandried mortar is basically regret in mineral form.

Maintenance Tips to Keep It Looking Sharp

- Repoint small cracks earlytiny gaps become water highways.

- Keep sprinklers from blasting the mailbox daily (constant moisture accelerates staining and wear).

- Clean gently: soft brush and mild cleaner; harsh acids can damage mortar and brick.

- If you seal brick, use a breathable masonry sealer and follow manufacturer instructions.

of Real-World Brick Mailbox Experience (The Part You’ll Thank Later)

The first time you build a brick mailbox, you learn two truths: (1) masonry is incredibly satisfying,

and (2) gravity is a strict supervisor who does not accept “close enough.” I’ve seen DIYers start with

big confidence, a perfect Pinterest photo, and exactly one level… that they never actually use. Don’t

be that person. Your level is not decoration; it’s the therapist that keeps your mailbox upright.

One of the best “pro habits” you can steal is cleaning as you go. Mortar smears feel harmless in the

momentlike frosting on a cupcake. But once they cure, you’ll be chiseling and scrubbing like you’re

restoring an ancient ruin. Keep a small bucket of water and a sponge nearby, wipe drips early, and

avoid over-wetting joints. A gentle touch now saves aggressive cleaning later.

Another lesson: brick layout is half math, half manners. If you plan your courses and cuts ahead of time,

the bricks behave. If you don’t, you’ll hit the “one-inch problem” where everything is perfect until the

last brick needs to be exactly 0.83 inches widealso known as “not a real brick.” Dry-fitting a few courses

and planning where cuts will land is the difference between a clean pattern and a column that looks like

it’s trying to escape.

Foundation prep is where experienced builders quietly win. The folks who complain that their mailbox leaned

after one winter almost always skipped compaction or went too shallow for their conditions. If your area

freezes hard, treat frost seriously. A deeper strategywhether that’s a deeper center pier, a more robust

footing plan, or code-compliant depthoften costs a little more effort up front and saves a full rebuild later.

Nothing is more demoralizing than realizing your “permanent” mailbox has become a seasonal decoration.

Finally, consider how you actually use the mailbox. If you get packages, choose an insert that can handle them.

If you send outgoing mail, think about a flag solution or a visible indicator. And if your street gets plowed,

add a buffer so snowbanks don’t bury the door. The best brick mailbox isn’t just prettyit’s practical. The goal

is to build something you don’t have to think about again… except when you catch yourself admiring it on the way

back from taking out the trash. (Yes, that will happen.)

Conclusion

A well-built brick mailbox is a small structure with big impact: stronger than a standard post, more secure,

and a serious upgrade to curb appeal. The secret is not “fancy brickwork”it’s smart planning, USPS-friendly

placement, a foundation that fits your climate, a reinforced core, and careful finishing. Build it right once,

and your mailbox becomes the kind of neighborhood detail that quietly makes your whole home look more put-together.