Table of Contents >> Show >> Hide

- What a Toilet Flush Valve Does (and Why It Fails)

- Is It Really the Flush Valve? Quick Diagnosis Before You Buy Parts

- Tools and Parts You’ll Need

- Step-by-Step: How to Replace a Flush Valve in a Standard Two-Piece Toilet

- Step 1: Turn Off the Water and Drain the Tank

- Step 2: Disconnect the Water Supply Line

- Step 3: Remove the Toilet Tank (Yes, It’s AwkwardNo, You’re Not Weak)

- Step 4: Remove the Old Flush Valve

- Step 5: Install the New Flush Valve (Gaskets: The “Read This Twice” Part)

- Step 6: Replace the Tank-to-Bowl Gasket

- Step 7: Reinstall the Tank on the Bowl

- Step 8: Reconnect the Flapper/Chain (or Canister Linkage)

- Step 9: Reconnect the Refill Tube and Water Supply

- Step 10: Turn the Water On and Test Everything

- If You Have a Canister/Tower-Style Flush Valve (Including Many Kohler-Style Setups)

- Troubleshooting After Flush Valve Replacement

- Common Mistakes (So You Don’t Learn the Hard Way)

- Maintenance Tips to Make Your New Flush Valve Last

- When to Call a Plumber

- Real-World Experiences and Lessons From Replacing a Flush Valve (So You Can Skip the “Oops” Phase)

- Conclusion

Your toilet is supposed to flush and then go back to quietly minding its own business. If it’s running nonstop, “ghost flushing” at 2 a.m.,

or leaking into the bowl like it’s trying to recreate Niagara Falls in miniature, the flush valve may be the culprit.

The good news: replacing a toilet flush valve is a very doable DIY project for a standard two-piece toiletand it’s usually cheaper than paying

a plumber to come over, sigh dramatically, and tighten one nut.

This guide walks you through how to replace a flush valve in a toilet step by step, with the right tools, the right parts, and the right amount

of patience (which is still more than your toilet currently has). We’ll also cover common canister/tower-style systems, troubleshooting, and the

small details that prevent big leaks.

What a Toilet Flush Valve Does (and Why It Fails)

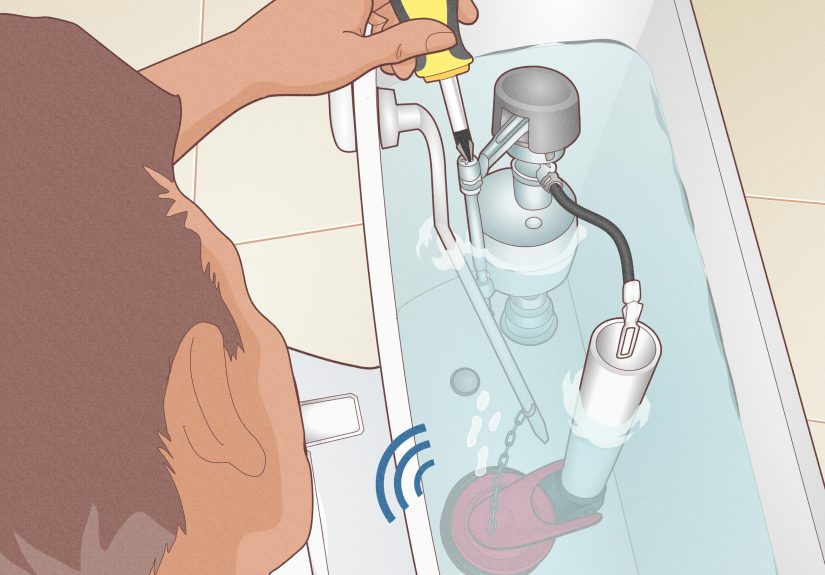

The flush valve is the assembly in the center of the toilet tank that releases water into the bowl when you flush. It typically includes:

an overflow tube, the valve seat/opening, and a seal mechanism (a flapper or a canister/tower seal). When you flush, the seal lifts,

water rushes into the bowl, and the tank refills.

Over time, rubber parts harden, warp, or get grimy. Mineral buildup can rough up sealing surfaces. Chains get misadjusted. Plastic parts can crack.

Result: a running toilet, weak flushes, or a leak that slowly drains your tank (and your wallet).

Is It Really the Flush Valve? Quick Diagnosis Before You Buy Parts

The “Food Coloring” Leak Test (15 Minutes, Zero Plumbing Credentials Required)

If you suspect water is leaking from the tank into the bowl, add a few drops of food coloring to the tank water (don’t flush).

Wait about 10–15 minutes. If colored water shows up in the bowl, water is passing the seal at the flush valve.

That might mean you only need a new flapper or sealor it might mean the flush valve seat is damaged and the whole valve should be replaced.

When You Can Replace Just the Flapper/Seal (and When You Should Replace the Whole Flush Valve)

- Try a flapper/seal first if the toilet runs intermittently, the flapper looks warped, slimy, or stiff, or the chain is too tight/too loose.

-

Replace the whole flush valve if the overflow tube is cracked, the valve seat is rough/damaged, the flapper mounting is integrated,

you’re switching sizes, or you want a full refresh after years of service.

Also: if your toilet has a canister/tower-style flush (common on some brands), the “seal” may be a circular gasket under the canister.

Those often fail and can sometimes be replaced without removing the tankmore on that below.

Tools and Parts You’ll Need

Tools

- Adjustable wrench

- Large channel-lock pliers (or a spud wrench if you have one)

- Screwdriver (usually flathead and/or Phillips)

- Bucket and towels (the true heroes of DIY plumbing)

- Sponge or wet/dry vac (optional, but makes draining easier)

- Rubber gloves (optional, but your hands will thank you)

Parts (Flush Valve Kit + “While You’re In There” Items)

- Replacement flush valve (match the size: typically 2-inch or 3-inch)

- Tank-to-bowl gasket (often included in kits, but not always)

- New tank bolts and washers (highly recommended if yours are corroded)

- Flapper (or canister seal) and chain (if not included)

How to Tell if You Need a 2-Inch or 3-Inch Flush Valve

The flush valve size refers to the diameter of the opening at the bottom of the tank where water exits.

Many toilets use a 2-inch opening; some use a larger 3-inch opening for a faster, more powerful flush.

If you’re not sure, remove the tank lid and measure the opening under the flapper/canister (or check the model info inside the tank).

Buying the wrong size is a rite of passagelet’s skip that tradition.

Step-by-Step: How to Replace a Flush Valve in a Standard Two-Piece Toilet

This walkthrough is for a typical gravity-flush, two-piece toilet. One-piece toilets, pressure-assisted toilets, and some specialty models can differ.

If your tank looks like it has a spaceship engine inside, pause and look up your toilet model’s parts diagram.

Step 1: Turn Off the Water and Drain the Tank

- Turn the shutoff valve (usually behind the toilet) clockwise until it stops.

- Flush the toilet to drain most of the water from the tank.

- Hold the handle down to let more water out.

- Sponge or vacuum out the remaining water from the tank into a bucket.

Pro tip: Put a towel under the tank area. Gravity is undefeated, and water always finds the one spot you didn’t protect.

Step 2: Disconnect the Water Supply Line

- Place a small bucket or towel under the supply connection.

- Use an adjustable wrench to loosen the nut connecting the supply line to the bottom of the fill valve.

- Let any remaining water drip out.

Step 3: Remove the Toilet Tank (Yes, It’s AwkwardNo, You’re Not Weak)

- Inside the tank, locate the two (sometimes three) tank bolts at the bottom.

- Hold the bolt head inside the tank with a screwdriver while loosening the nut underneath with a wrench.

- Remove nuts and washers. If they’re rusted, go slow. If they’re really rusted, you may need penetrating oil.

- Gently lift the tank straight up and place it on a towel (or in a tub) so it doesn’t chip.

If the tank doesn’t lift easily, it may be stuck to the bowl gasket. Wiggle gentlyno need to wrestle your porcelain throne into submission.

Step 4: Remove the Old Flush Valve

- Flip the tank upside down on a padded towel.

- Remove the large nut on the bottom of the flush valve (often called the spud nut).

- Pull the old flush valve out from inside the tank.

- Clean the tank hole and surrounding area of mineral buildup and old gasket residue.

Cleaning matters: a new gasket sealing against old gunk is like trying to stick a bandage to wet sunscreen. Technically possible, emotionally upsetting.

Step 5: Install the New Flush Valve (Gaskets: The “Read This Twice” Part)

- Insert the new flush valve through the tank opening from the inside.

-

Ensure the rubber gasket is positioned correctly (usually inside the tank, seated against the porcelain around the hole).

Some kits include additional washersfollow the kit diagram. - Thread the large mounting nut onto the flush valve from the underside of the tank.

- Hand-tighten first, then snug it carefully with pliers. Don’t over-tightenporcelain does not forgive.

- Align the overflow tube so it won’t interfere with the flapper/canister movement.

Step 6: Replace the Tank-to-Bowl Gasket

The tank-to-bowl gasket sits between the tank and the bowl, sealing the connection where water flows from tank to bowl.

If your kit includes a new one, use it. If it doesn’t, consider buying one anyway. Reusing a flattened old gasket is like reusing gum:

possible, but deeply questionable.

- Slide the new gasket onto the flush valve outlet on the underside of the tank.

- Make sure it sits evenly and isn’t twisted.

Step 7: Reinstall the Tank on the Bowl

- Set the tank carefully on the bowl, lining up the bolt holes.

- Insert the tank bolts with rubber washers inside the tank.

- From underneath, add washers and nuts, then tighten evenlyalternating sides so the tank sits level.

- Stop when the tank is stable and doesn’t rock. Over-tightening can crack the tank.

Step 8: Reconnect the Flapper/Chain (or Canister Linkage)

- Attach the flapper to the flush valve pegs (if flapper-style).

- Connect the chain to the flush handle lever with a little slackusually about 1/4 to 1/2 inch.

- Make sure the flapper lifts cleanly and seats fully when dropped.

Chain too tight = flapper never seals = running toilet. Chain too loose = handle does nothing = you angrily flush twice like it’s a protest vote.

Step 9: Reconnect the Refill Tube and Water Supply

- Clip the refill tube to the overflow tube (don’t shove it down insidekeep it above the waterline to prevent backflow issues).

- Reconnect the water supply line and tighten the nut snugly.

Step 10: Turn the Water On and Test Everything

- Turn the shutoff valve counterclockwise to restore water.

- Let the tank fill and check for leaks at the supply connection, tank bolts, and tank-to-bowl area.

- Flush several times. Confirm the flapper/canister closes fully and the tank refills to the proper level.

If You Have a Canister/Tower-Style Flush Valve (Including Many Kohler-Style Setups)

Some toilets use a canister (a vertical “tower” that lifts) instead of a standard flapper. If your toilet “runs” and the canister seal is worn,

you may be able to replace the seal without removing the tankdepending on the design.

Option A: Replace Only the Canister Seal

If the flush valve tower lifts off or twists out, you can often remove the old circular seal and install a new one.

This is a great fix when the toilet leaks into the bowl but the plastic parts are otherwise fine.

Option B: Replace the Entire Canister Flush Valve Assembly

If the tower/guide is cracked, warped, or the seat is damaged, a full replacement may be smarter. Some assemblies twist-lock into place;

others require tank removal. When in doubt, match your toilet model to the manufacturer’s parts list so you get the correct kit.

Troubleshooting After Flush Valve Replacement

Problem: Water Leaks Between Tank and Bowl

- Tank-to-bowl gasket may be misaligned, twisted, or the wrong size.

- Tank bolts may be unevenly tightened; tighten both sides gradually and evenly.

- Cracked gasket or missing washer can cause dripsdouble-check your stack order.

Problem: Tank Keeps Running

- Flapper/seat isn’t sealing (chain too tight, flapper misaligned, or seat dirty).

- Water level is too high and spilling into the overflow tube; adjust the fill valve float to lower the fill level.

- On canister systems, the seal may not be seated correctly.

Problem: Weak Flush or “Half Flush”

- Chain is too loose; tighten one link at a time until the flapper lifts fully.

- Flapper closing too fast; some flappers have adjustable floats or settings.

- Tank water level too low; raise it slightly (but keep it below the top of the overflow tube).

Problem: Leaks at the Supply Connection

- Supply nut needs a gentle snugging.

- If it still leaks, the supply line washer may be wornreplace the supply line.

Common Mistakes (So You Don’t Learn the Hard Way)

- Over-tightening plastic nuts: snug is good; gorilla-tight is how tanks crack.

- Forgetting to clean sealing surfaces: debris prevents a watertight gasket seal.

- Mixing bolt washers: rubber washers go inside the tank; metal washers typically go outside.

- Buying the wrong size: measure that flush opening2-inch vs 3-inch matters.

- Skipping a new tank-to-bowl gasket: it’s inexpensive and saves rework.

Maintenance Tips to Make Your New Flush Valve Last

- Clean mineral buildup inside the tank occasionally, especially in hard-water areas.

- Avoid drop-in tank cleaners that can degrade rubber seals and flappers over time.

- If the toilet starts “ghost flushing,” test earlysmall leaks grow into bigger annoyances.

- Replace rubber parts (flapper/seal) proactively every few years if your water is harsh.

When to Call a Plumber

DIY is greatuntil it isn’t. Consider calling a plumber if:

- You have a one-piece, pressure-assisted, or specialty toilet with unusual parts.

- The shutoff valve won’t close fully (or starts leaking when you touch it).

- Tank bolts are seized and you risk cracking the tank trying to remove them.

- You discover cracks in the tank or bowl. (Cracks + water + gravity = bad day.)

Real-World Experiences and Lessons From Replacing a Flush Valve (So You Can Skip the “Oops” Phase)

Most people don’t replace a toilet flush valve because it sounds like a fun Saturday. It’s usually a “Why is my toilet whispering at me?”

moment that turns into a trip to the hardware store. And that’s exactly where a few predictable, very human things happen.

First: the mystery of the missing measurement. DIYers often stand in the aisle holding a flush valve kit, thinking,

“This looks right,” the way you might pick a suitcase by vibes. The trick is to measure (or confirm) whether you have a 2-inch or 3-inch opening.

It’s a small step that prevents the classic experience of returning a perfectly good part because it’s perfectly wrong for your toilet.

Second: the tank bolt surprise. Even when the flush valve is the real issue, rusty tank bolts can steal the show.

A lot of people discover that the bolts are more “historical artifact” than “fastener.” If yours look corroded, replacing them during the job

is less of an “extra” and more of an investment in not having to repeat the job next month. The best experiences are the ones where you do it once.

Third: the gasket alignment dance. Many “my toilet leaks after I replaced the flush valve” stories come down to gaskets:

a tank-to-bowl gasket slightly off-center, a rubber washer flipped, or a seal sitting on a ridge of mineral buildup. In real bathrooms,

parts don’t magically seat themselves like they do in instruction diagrams. The practical move is to slow down at gasket steps:

clean the porcelain, check that rubber sits flat, and tighten evenly.

Fourth: the chain adjustment Goldilocks problem. It’s easy to underestimate how much a tiny chain affects performance.

Too tight and your toilet runs. Too loose and you get that sad “half flush” that feels like your toilet is doing the bare minimum.

People tend to fix this fastest when they adjust one link at a time, test flush, and repeat until the flapper lifts fully and seals cleanly.

It’s not glamorous, but it’s the difference between “fixed” and “fixed-ish.”

Fifth: the emotional arc of leak-checking. The first refill after reinstalling the tank is always a little dramatic:

you’re crouched there, staring at bolts and seams like a detective in a crime show, waiting to see if anything drips.

The experience gets calmer when you check systematicallysupply connection first, then tank bolts, then the tank-to-bowl seamrather than panicking

and tightening everything randomly (which can create new problems).

Finally: the unexpected win. Many people replace a flush valve to stop a leak and end up with a noticeably better flush,

quieter refills, and fewer “phantom” noises. The toilet becomes boring againin the best way. And in DIY plumbing,

boring is the highest compliment you can give.

Conclusion

Replacing a flush valve in a toilet isn’t complicated, but it rewards careful steps: shut the water off, drain the tank, remove the tank safely,

replace the valve with correct gasket placement, and reinstall everything evenly. Do that, and you’ll fix running toilets, stop leaks into the bowl,

and get your bathroom back to its natural state: quiet, reliable, and not plotting against you.